What powers a significant portion of America’s industrial base, yet goes unnoticed by most people? Meet the industrial boiler.

Industrial boilers operate quietly across different types of facilities, supplying the heat that keeps many industrial processes running day after day. They are rarely visible to the public but deeply embedded in the systems that support industrial production across the country. As these systems age and efforts expand to improve efficiency, maintain reliable operations, and reduce emissions, attention is increasingly turning to boiler modernization.

While discussions often focus on technological or emission-related outcomes, they also raise important questions about how the workforce that operates and maintains these systems could be impacted and how modernization efforts intersect with industrial jobs.

What is an industrial boiler?

An industrial boiler is a pressure vessel used across manufacturing, processing, mining, and refining industries to produce steam or hot water for industrial processes. They are commonly found in sectors such as food processing, chemicals, refining, pulp & paper, and primary metals.

Unlike residential or commercial systems, industrial boilers are designed to operate continuously, handle high pressures and temperatures, and meet the demands of industrial-scale operations. Industrial boilers play a foundational role across US industry.

Why do industrial boilers matter?

Industrial boilers play a central role in providing heat across many energy-intensive sectors that form the backbone of the US economy. As a result, industrial boilers account for a meaningful share of on-site energy use and combustion-related emissions across many sectors, with impacts varying by end use, fuel type, and operating conditions. For example, one recent analysis illustrates the scale of industrial boilers’ contribution to industrial energy use: thermal processes accounted for 75 percent of US industrial final energy demand in 2018, and conventional industrial boilers used for steam generation consumed 17 percent of that thermal energy (excluding cogeneration).

Many industrial boilers in use today were installed decades ago and designed around earlier efficiency standards, fuel types, control systems, and the technological capabilities available at the time. While individual components can be repaired, replaced, or upgraded over time, these changes do not always amount to full system modernization. In some cases, modernization requires more than a component swap, shaping how and when broader upgrades occur.

Moreover, changing an industrial boiler system is not just a technical or operational decision. The impact of upgrading or replacing industrial boilers can influence how these systems operate and are maintained, shaping workforce roles, skill requirements, and day-to-day responsibilities at industrial facilities.

Where are industrial boilers concentrated?

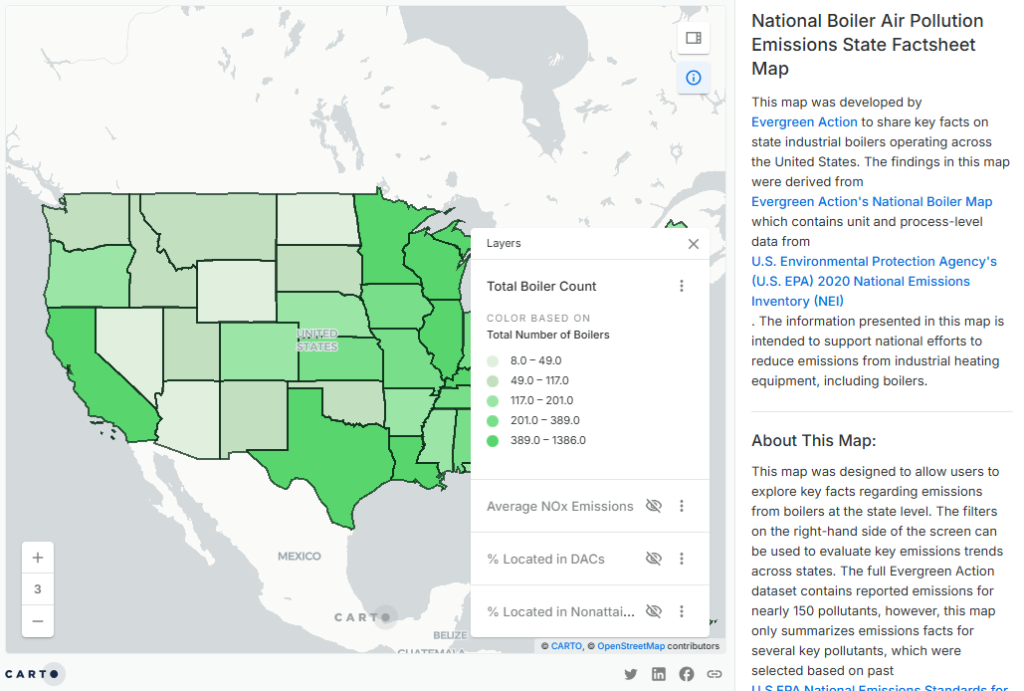

Recent mapping from Evergreen Action shows that industrial boilers are not evenly distributed across the country, with states such as California, Illinois, Minnesota, Massachusetts, and Texas hosting some of the highest concentrations nationwide. Beyond state-level concentration, Evergreen Action’s analysis shows that industrial boilers are often clustered within established industrial and manufacturing hubs, closely aligned with where industrial activity is most concentrated. This clustering reflects the role boilers play in supporting energy-intensive industrial processes, rather than being evenly distributed across all regions nationwide.

Understanding where industrial boilers are concentrated can impact modernization planning and how workforce capacity and skill demands are considered as systems are upgraded or replaced. Taken together, understanding the importance and concentration of industrial boilers helps clarify where modernization opportunities are likely to emerge and where emission-reduction efforts may be most impactful.

Three workforce considerations in industrial boiler modernization.

While industrial boiler modernization is often discussed through an energy or emissions lens, the pace, scale, and location of these upgrades also carry direct implications for the industrial workforce. These discussions can shape staffing needs, skill requirements, and job opportunities across facilities. The following workforce considerations highlight key factors to keep in mind as industrial boiler modernization moves forward.

1. The continued need for a skilled workforce

Even as industrial boiler systems modernize, they will continue to rely on a skilled workforce to operate, maintain, and repair high-pressure steam and hot-water systems. National labor data shows that roles such as stationary engineers and boiler operators remain central to boiler operations across industrial facilities. According to the Bureau of Labor Statistics, occupations associated with industrial boiler operation and maintenance are expected to see approximately 3,800 job openings per year, on average, driven primarily by replacement needs, with overall employment projected to grow by about two percent over the next decade.

As modernization efforts move forward, workforce demand is therefore shaped less by whether these jobs exist and more by how roles, skill requirements, and training pathways evolve alongside changes to industrial boiler technologies.

2. Emissions and health impacts

Industrial boilers are a significant source of combustion-related air pollutants, including nitrogen oxides, particulate matter, sulfur oxides, and other hazardous air pollutants released during industrial heat generation. Additionally, industrial boilers are responsible for up to 10 percent of industrial carbon emissions and six percent of industrial NOx emissions nationwide. Exposure to industrial air pollution is associated with increased risks of respiratory illness, cardiovascular disease, and other adverse health outcomes for workers and surrounding communities.

In facilities where industrial boilers operate continuously, these emissions shape the day-to-day environment in which workers operate and maintain equipment. Modernization efforts that reduce these types of emissions will have implications beyond environmental performance, improving air quality and supporting healthier working conditions for the workforce operating in and around these systems.

3. Infrastructure readiness and challenges

The modernization of industrial boilers often requires more than changes to the equipment itself. In some instances, existing electrical and energy infrastructure may not be sufficient to support new or electrified industrial heat systems without upgrades. Constraints related to on-site electrical capacity, distribution systems, and integration with existing processes can affect both the timing and feasibility of modernization efforts.

These infrastructure-related constraints mean that modernization is often not a simple equipment swap, but a broader system-level effort that may require additional site preparation, electrical upgrades, and coordination across facilities and utilities. As a result, these dynamics can influence not only the pace or sequencing of modernization, but also the scope of work required, shaping workforce needs for planning, coordination, and the deployment of skilled labor as facilities prepare for new systems.

Final thoughts.

Taking all these considerations together, the modernization of industrial boilers is not solely about reducing emissions or improving energy performance. Decisions about how and when these systems are upgraded intersect with the continued need for a skilled workforce, the potential for improved air quality and health outcomes, and the practical realities of infrastructure readiness at industrial facilities. Considering all these factors helps provide a bigger picture of what industrial boiler modernization looks like in practice and the conditions required to support it over time.